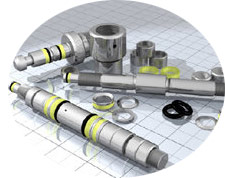

Totally re-engineered concepts have resulted in a unique mandrel design capable of meeting a wide range of industry needs.

The cornerstone of this new mandrel is its revolutionary segment and cam assemblies. During expansion, the segments remain parallel to the axis of the tube, minimizing bending stress. The result is greater strength, longer life, less leakage, and reduced tube marking when compared to existing products.

Significant improvement in performance of our cams and segments along with ultra high strength alloys are ideal for high pressure applications.

Static Condition: When in a relaxed (static) state, the beveled cams fit snugly against the segment assemblies. Since there is no force applied, the segments remain firmly in place.

Loaded Condition: Once hydraulic pressure is applied to the mandrel, the beveled cams are forced toward each other. As the cams move, the individual segments are forced symmetrically outward, held togeter by the band