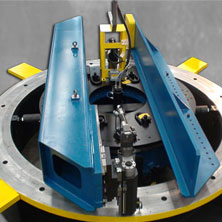

For machining large flanges 73.5 – 199 inches (1866.9 – 5054.6 mm) in diameter, and featuring a center machine clearance designed to fit over 24 inch (609.6 mm) diameter kingpins, this Circular Mill can be configured for powerful milling, single-Point machining and grinding operations. Extraordinary rigidity, versatility, and power are at your fingertips – this machine can handle your toughest large flange machining jobs quickly and efficiently. For smaller ranges view the FF7200 or FF8200 Flange Facers.

Quality Machine Design Provides Rigid, Power-Packed Performance

Flexible and Versatile

Rapid Setup & Operation

Applications include:

ID Mounting Diameters:

Milling Diameters:

Min Turning Arm Swing Diameter:

Max Turning Arm Swing Diameter: