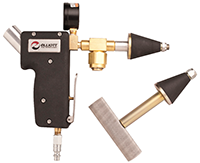

Operating the RECON 1500 Tube Leak Test Gun is simple. With the air supply connected, plug one tube end with the test gun and the other end with the T-Handle Plugging Tool. Press the lever trigger and the Venturi System quickly and efficiently evacuates the tube. Then monitor the gauge for loss of vacuum, which indicates a tube leak.

The RECON 1250 and 2500 are simple to operate. Connect the air supply, insert the seals into both sides of the tube ends and pressurize the tubes. Then monitor the gauges for drops in air pressure, which indicate a tube leak..