The Model J is a compact tube beveling tool that is small enought to work in a 1 1/2" wide area, yet is powerful enough to bevel tubes up to 2" O.D.

Specifically designed for quick turnaround, single tube replacements and dutchman applications, the Model J can reduce downtime by reducing the amount of cutting and welding required.

The right-angle design and the wrench-feed at the back of the head makes it ideal for working in tight spaces. It features attached, replaceable wrenches for both the internal locking and the tool feed.

The Model OD is a compact tube beveling tool that is small enough to work in a 1 1/2" wide area, yet is powerful enough to bevel tubes up to 2 1/4" O.D.

Specifically designed for small diameter machining, the OD clamp allows for outside beveling, facing and even inside beveling for projects where the tube I.D. is too small for internal locking. It is also ideal for quick turnaround, single tube replacements and window weld applications.

The OD features a narrow head, right-angle design and a compact feed handle making it ideal for working in tight spaces.

The Model BG22 tool features a narrow head design to work in tight clearances. Just 1.6" wide, the head is made from strong, lightweight titanium steel.

The gear sets are designed for maximum strength and durability and deliver the combination of speed and torque required to perform a wide variety of end prep work.

Use the popular, patented Multi-Prep® tool to add even more productivity.

The sliding tool holder is standard on the MOdel BG22. This accepts all of the standard sliding cutters.

The Model BG44 has the power to machine tubes up to 3" O.D., yet is small enough to fit in a 2 5/8" wide ares.

Two pneumatic motors are available to match the tool ot your specific application. The BR90 produces 90 rpm for heavier walls and harder alloy materials.

The BR140 turns at 140 rpm. The higher speed of the BR140, and the electric model, produces higher speeds for use with replaceable carbide insert cutters like our patented Multi-Prep®.

With Multi-Prep®, you can clean the tube O.D., cut clad and overlay materials from fully covered tubes or from a single side, remove membranes from waterwall panels and O.D. bevel in a single pass.

The Mini-B is compact and lightweight with all of the power neccessary to machine tube ends from 5/8" I.D. to 3" O.D.

Weighing only 9 lbs., it is easy to use in overhead applications. The large working range makies it one of the most versatile tools available for O.D., I.D. and J beveling, facing, and other machining projects.

The compact wrench-feed design makes it ideal for working in tight spaces. The replaceable wrenches for both the internal locking and the tool feed are attached for operator convenience.

This design, proven over years of job-site use, delivers an extraordinary level of versatility for a wide variety of applications.

Choose between two reliable pneumatic motors or electric power. The MB55 is geared for heavy wall and hard alloy materials as well as removing stubs from headers. The MB110 delivers higher speed to turn specialty carbide insert cutters like our patented Multi-Prep®. With Multi-Prep®, you can clean the tube O.D., cut clad and overlay materials from fully covered tubes or from a single side, remove membranes from waterwall panels and O.D. bevel in a single pass.

Both MB's are available with wrench feed for working in tight places or the convenient side mounted crank feed.

The model BG50 delivers optimum power in a compact design. This combination makes it an ideal power unit for a variety of standard and custom applications.

As a beveling tool, it machines small to mid-sized tubes and pipes with heavy walls and/or hard alloy materials up to 5" O.D. Stand and specialty tooling is available to perform accurate O.D. and I.D. Beveling, stub removal from headers, seal-weld removal and even fin removal

The excellent power-to-weight ratio and reliable performance of the MS enables us to use it as a power unit for other applications. Install a custom J-prep tool holder and mill acurately for orbital welding.

Install a precision flange facera nd you can place any of a variety of finishes to clean and square flanges. Clean bolt patterns also up to 12" O.D.

The model MSX delivers high torque in a compact design for mid-sized, heavier wall and/or hard alloy materials up to 5 9/16" O.D.

The patented H&S gear design produces ideal cutting speed over the full range of the tool while the precision heavy duty bearings provide smooth, reliable performance for more accurate machining.

The rugged construction enables the MSX to withstand the abusive conditions of on-site work and deliver maximum production shift after shift.

The Power Beveler (PB 6 – 12) pipe bevelers are a combination of power, versatility, and reliability in a compact package. Designed to perform on-site machining with speed and accuracy, delivering optimal speed and torque combination to make short work of your pipe prep projects.

The model PB8 is designed specifically for the tough mid-sized pipe projects. Portable, powerful and reliable, the PB8 performs all of your on-site machining with the speed and accuracy that will lower your costs and keyou on schedule.

This design, proven over years of job-site use, delivers the optimum speed and torque combination to make short work of your pipe prep projects. Our patented heavy duty gear sets deliver the power to quickly cut heavy wall pipes of carbon, chrome moly or stainless steel materials.

The split-design allows the power unit to be quickly removed from the center shaft, reducing the heaviest lift to just 25 lbs. The shaft is locked into the pipe and the power unit is then placed onto the shaft.

Electric motor power is available upon request.

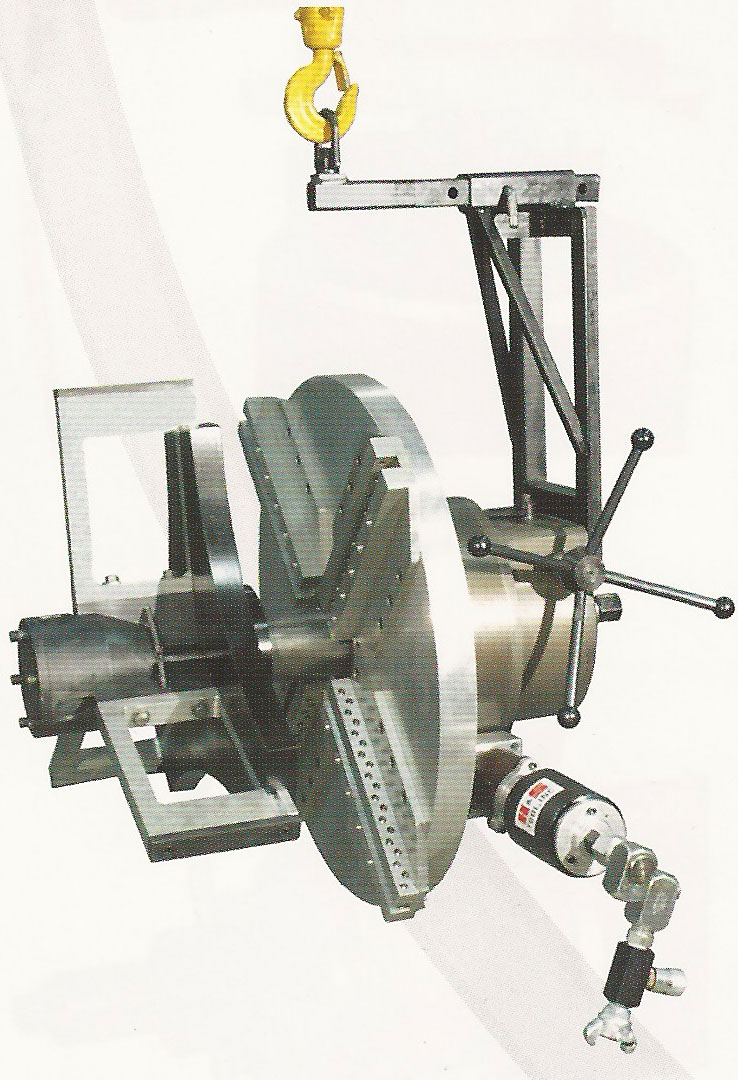

The H & S Model PB12 is a combination of power, versatility and reliability in compact package that allows a single operator to machine tube ends from 3 1/2" I.D. to 14" O.D.

Designed and built for on-site work, it performs equally well on standard and heavy wall materials. Custom H & S gearing ideally matches torque and cutter speed for smooth, accurate finished cuts. Electric motor power is available upon request.

To reduce the amount of weight being handled in a single lift, the centering mandrel can be installed in the pipe separately from the power unit. The mandrel locks the tool for torque-free operation and centers the tooling for accurate cuts. The power unit is then easily located on the center shaft.

The PB30 is a powerful, reliable I.D. mount end machining tool that will save you time and money for pipes from 8" I.D. to 30" O.D. The PB30 is compact and solidly built to withstand the abuse of production machining day after day, week after week.

Exclusive H&S gearing combines with variable speed control to produce the optimum speed for smooth, accurate cutting of different pipe sizes, wall thicknesses and materials.

A powerful 3.5 H.P. pneumatic motor is standard. Hydraulic power is an available option.

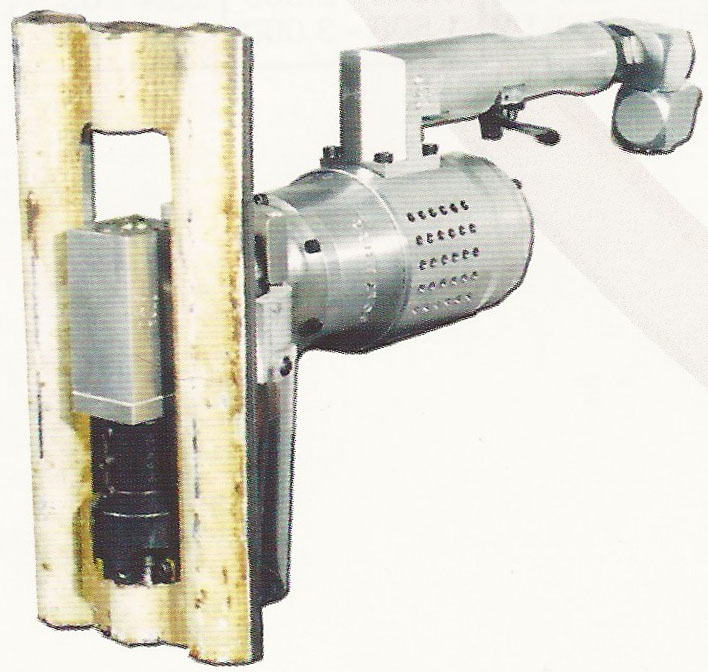

The Wizard MHS is an industry-leading high speed machine for volume production tube beveling and facing as well as membrane removal of panel walls.

The unique H&S pneumatic motor is lightweight and compact yet delivers true performance on tubes up to 3" O.D. It is protected by U.S. patent numbers 7653997 and 7673549.

The cutting heads use quality replaceable carbide inserts with multiple cutting edges for increased usable insert life. The heads are centered in the tube with hardened steel pilots which are availabe in .020" increments to accurately fit tube I.D.'s within the working range.

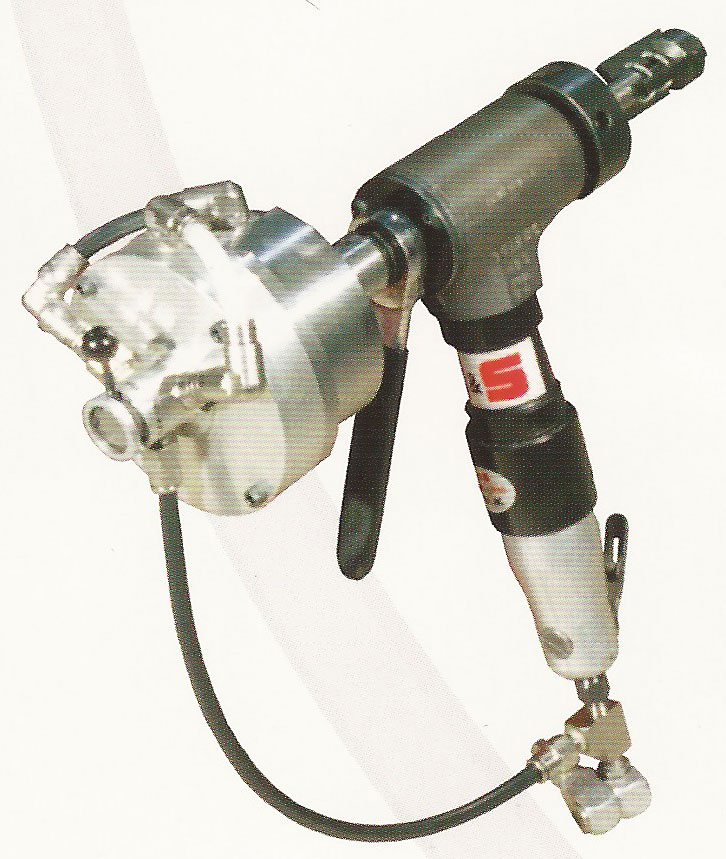

The AirLok is a time saving pneumatic lock actuating accessory. Ideal for condenser tubes and other large volume, small tube work, one finger activates the powerful air cylinder which expands the wedge locks and fasten the tool securely. Release is equally simple and effortless.

The AirLok is available on the models Mini-B, BR, MB and MS beveling tools. It can be used with a wide variety of standard and custom tooling to perform many types of end preparations projects.

TThis AirLok option can be added to your rental or purchased tool. The tools can be converted in the field from the conventional wrench lock version. It is easily converted back to the conventional feed method by unscrewing the cylinder and attaching the wrench/nut assembly.

A compact AirLok is available for the Mini-B for applications where space is limited.